Drag to turn 360°, move up and down

58 m3/h

15-500 microns

2 sizes

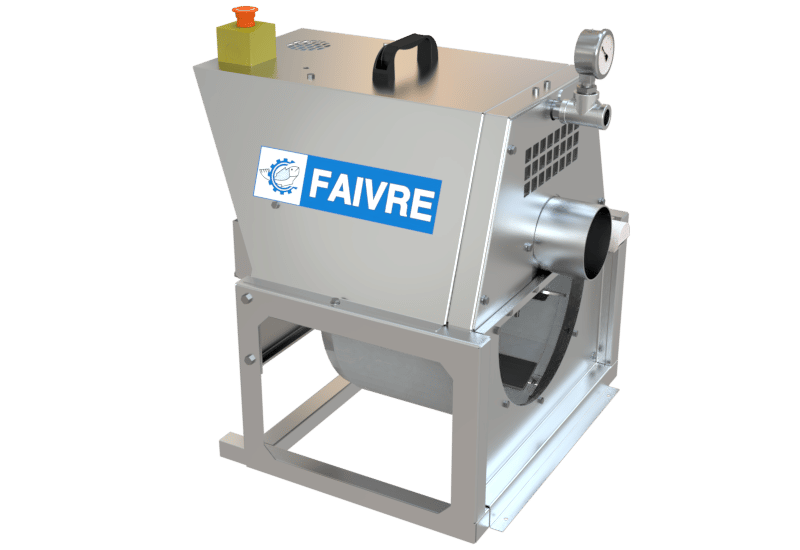

Flow rate up to 16 l/s (58 m3/h) at 100μ.

Its size and low weight make it particularly suitable for quick installation in tight spaces.

It is ideal for small recirculation systems, laboratories, test stations etc…

Made entirely of stainless steel or engineering plastic, it is completely resistant to corrosion.

Its 60 cm diameter drum runs at 8 rpm.

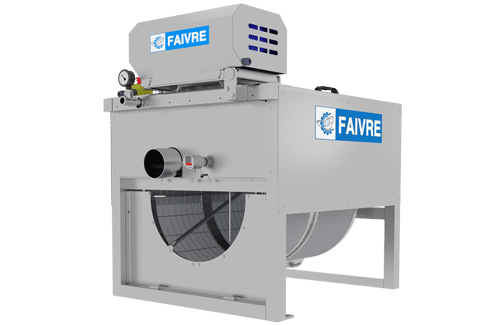

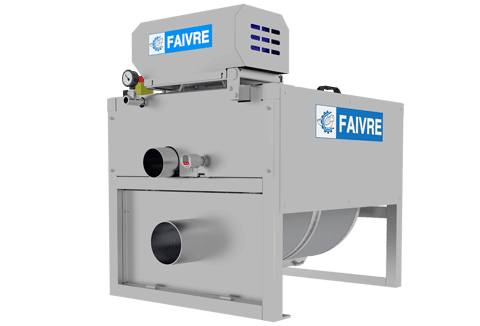

Drum filters – Drum Filters 60 Series

PRODUCT VARIATIONS

FRAME

INLET BY PIPES

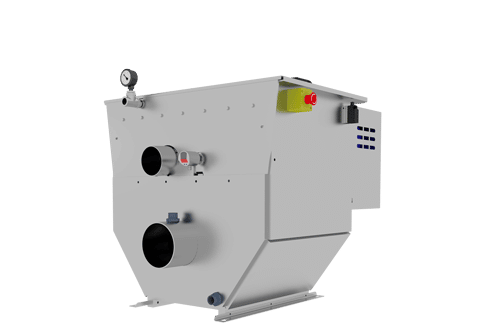

STAINLESS STEEL TANK

HDPE TANK

Drum filters – Drum Filters 60 Series

Product description

Simple, reliable and robust BDS system

Rotoclean 60 drum filters are equipped with a BDS (Belt Drive & Support system). The motor, ideally placed on the top of the drum filter, drives and supports the drum with one or more belts.

In 20 years of experience this system has proved its benefits:

– Smooth running by nature (no need using a frequency converter for a smooth start)

– Reliability over the years (more than 5 years without maintenance)

– Transmission does not break in case of drum blockage (e.g. if an object gets into the drum)

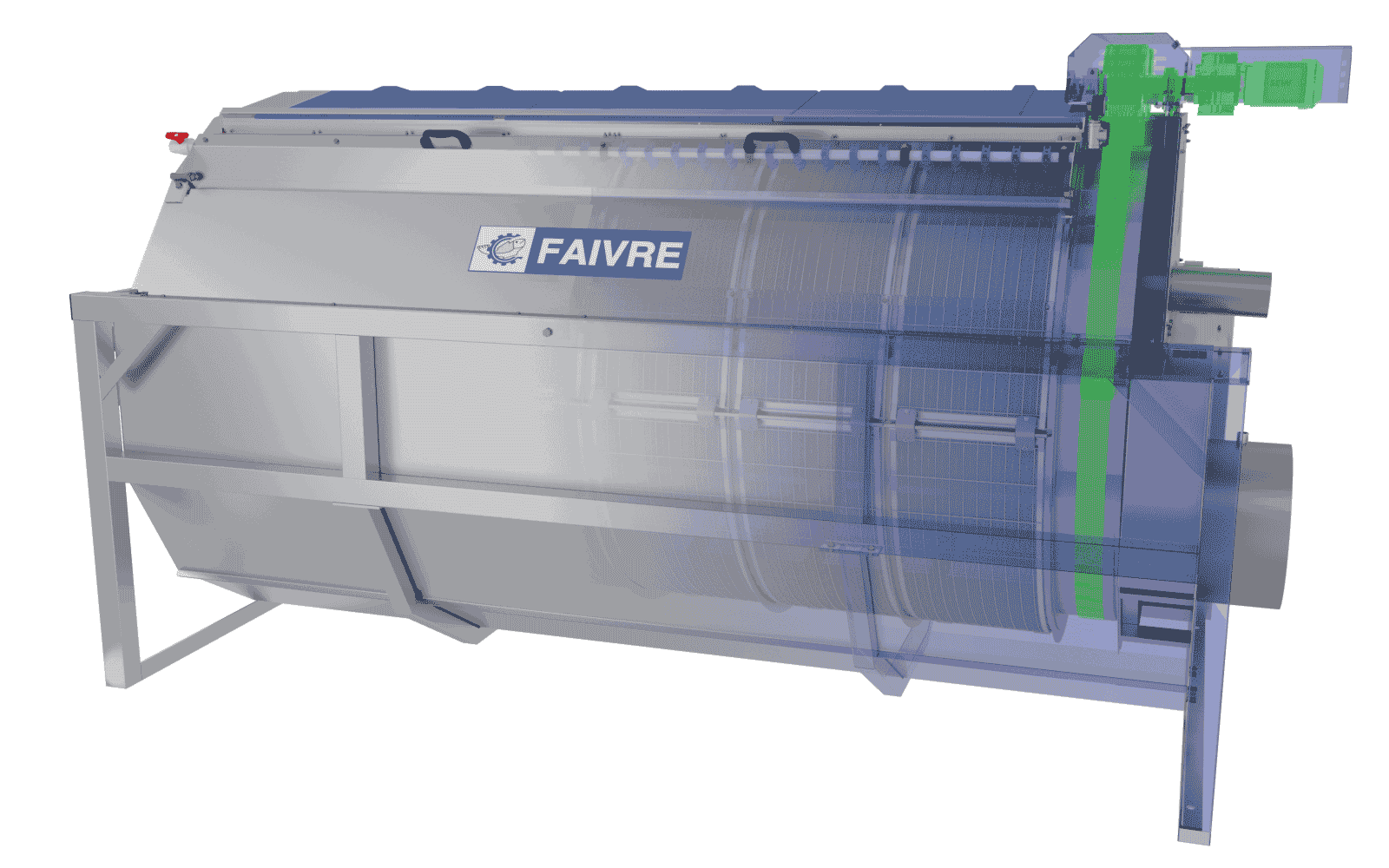

How a Rotoclean filter works

The operating system is simple: the filtered liquid flows into a rotating drum. This drum is made up of solid plates covered with stainless steel cloth. Impurities larger than the perforations are trapped against the inside of the plates. The drum runs slowly (3 to 8 rpm, depending on the model) and draws the impurities out of the water. A rinsing ramp located at the top of the drum cleans the plates to evacuate the impurities into the sludge outlet channel. FAIVRE filters have been designed to be corrosion resistant as they are entirely stainless steel and HDPE constructed. FAIVRE drum filters have very limited moving parts thanks to their exclusive belt-driven drum rotation and suspension system (BDS System). Maintenance is very minimized. The strength of these filters comes from the filter plates. Built according to a unique process, they can be replaced in a few minutes thanks to an exclusive fixing system. We therefore offer a complete range of filters that are efficient, robust and economical in use.

High quality stainless steel construction

Exclusive use of high quality stainless steel manufactured in Northern Europe.

– Stainless steel AISI 304L (4301) for fresh water as standard

– Stainless steel AISI 316L (4404) for sea water as standard

– Stainless steel DUPLEX (2205), SUPER DUPLEX (2507), HDPE and Titanium for warm sea water.

CCPU of the filter material can be supplied on request.

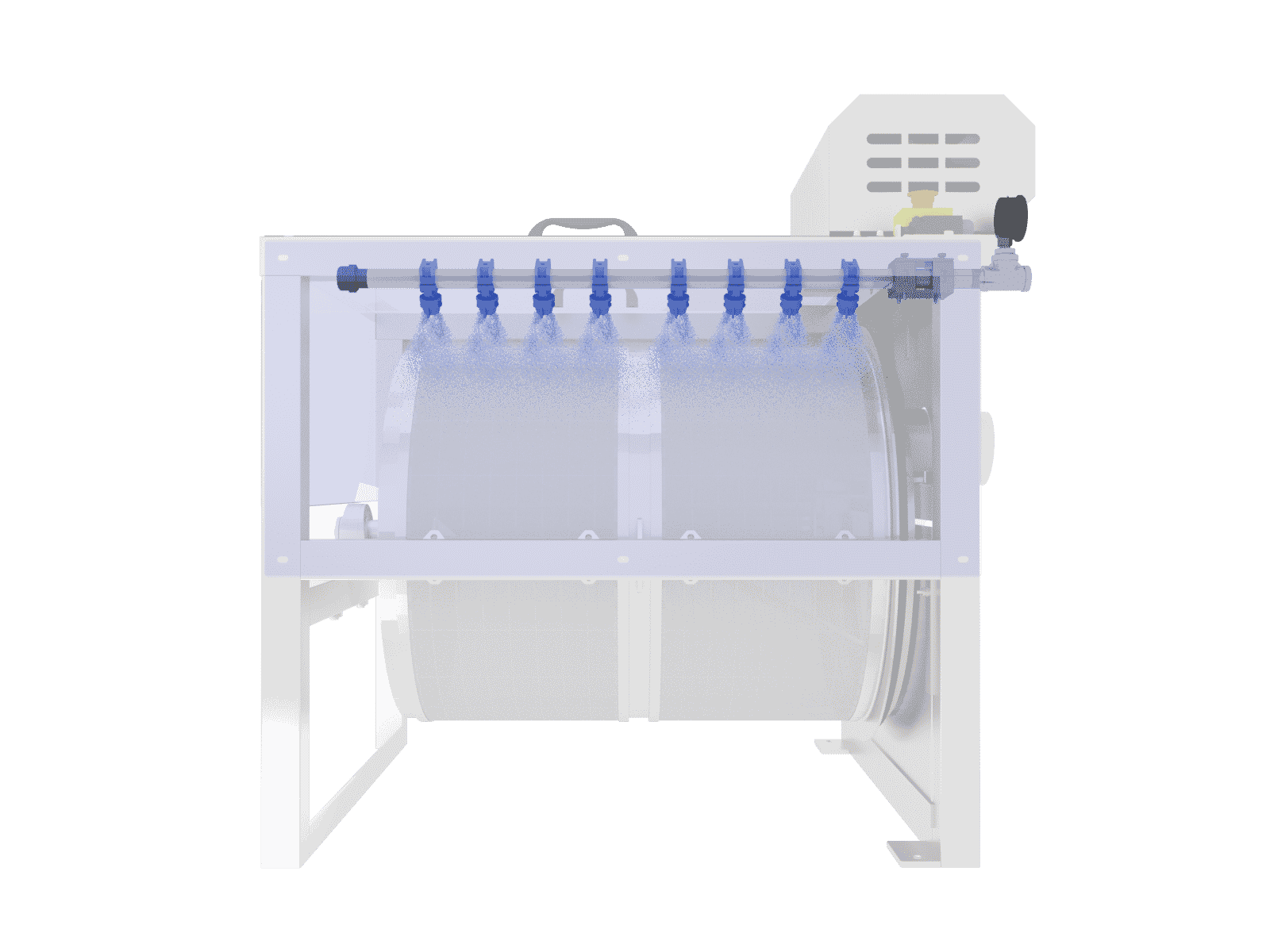

Rinse ramp with optimised water flow and pressure

The Rotoclean Series 60 drum filter is equipped with only 4 or 8 rinsing nozzles, which helps to save flushing water.

This saving is appreciated in small closed circuits where this filter is often used.

Furthermore, the pressure of the nozzles has been optimised in order to obtain a perfect rinsing of the mesh without damaging it.

Drum filters – Drum Filters 60 Series

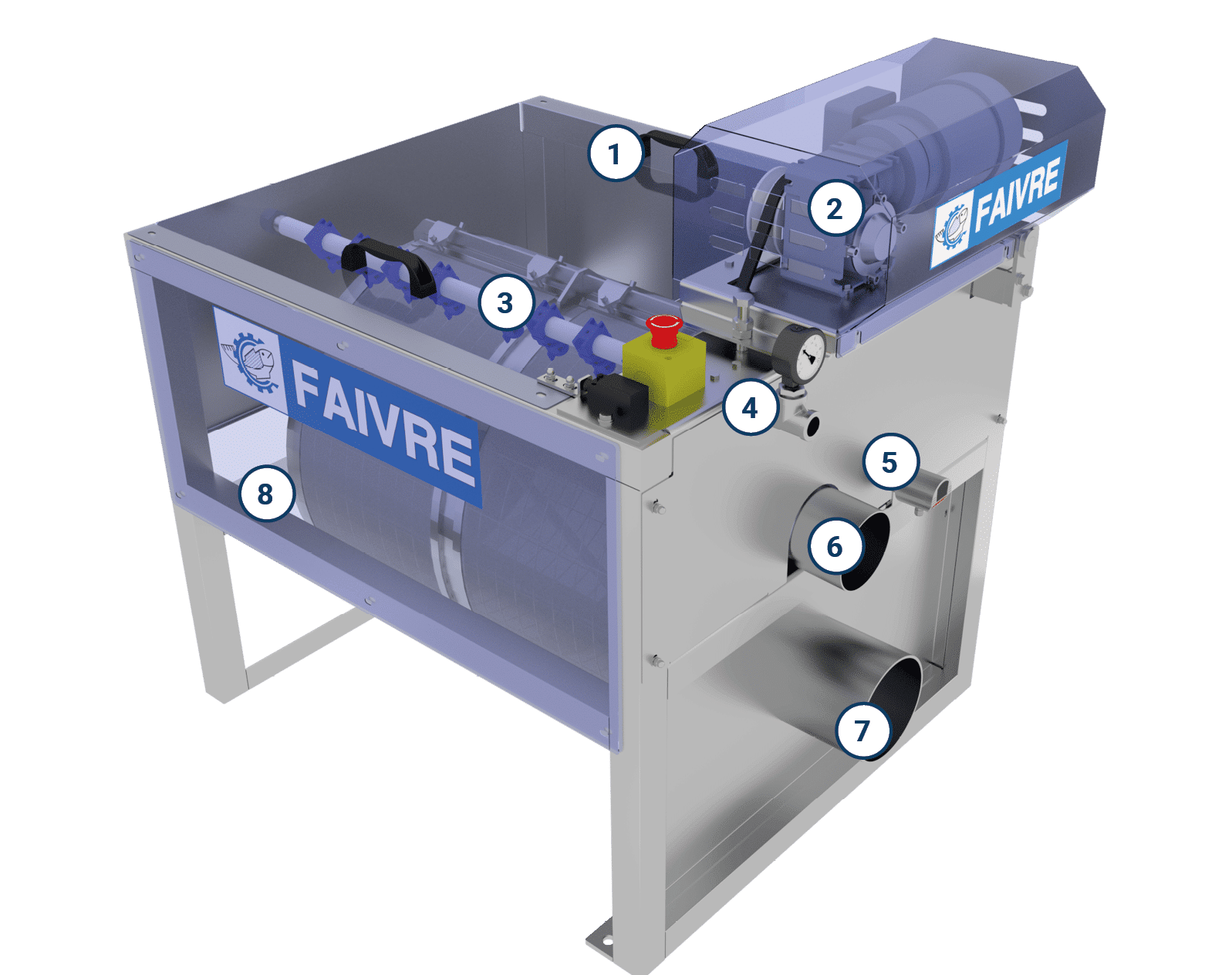

PRODUCT CHARACTERISTICS

- Removable cover

- IP55 Gearmotor

- Rinsing ramp

- Rinsing pump connexion with gauge pressure

- Level probe (option)

- Sludge outlet

- Water inlet

- Stainless steel drum

Drum filters – Drum Filters 60 Series

PRODUCT OPTIONS

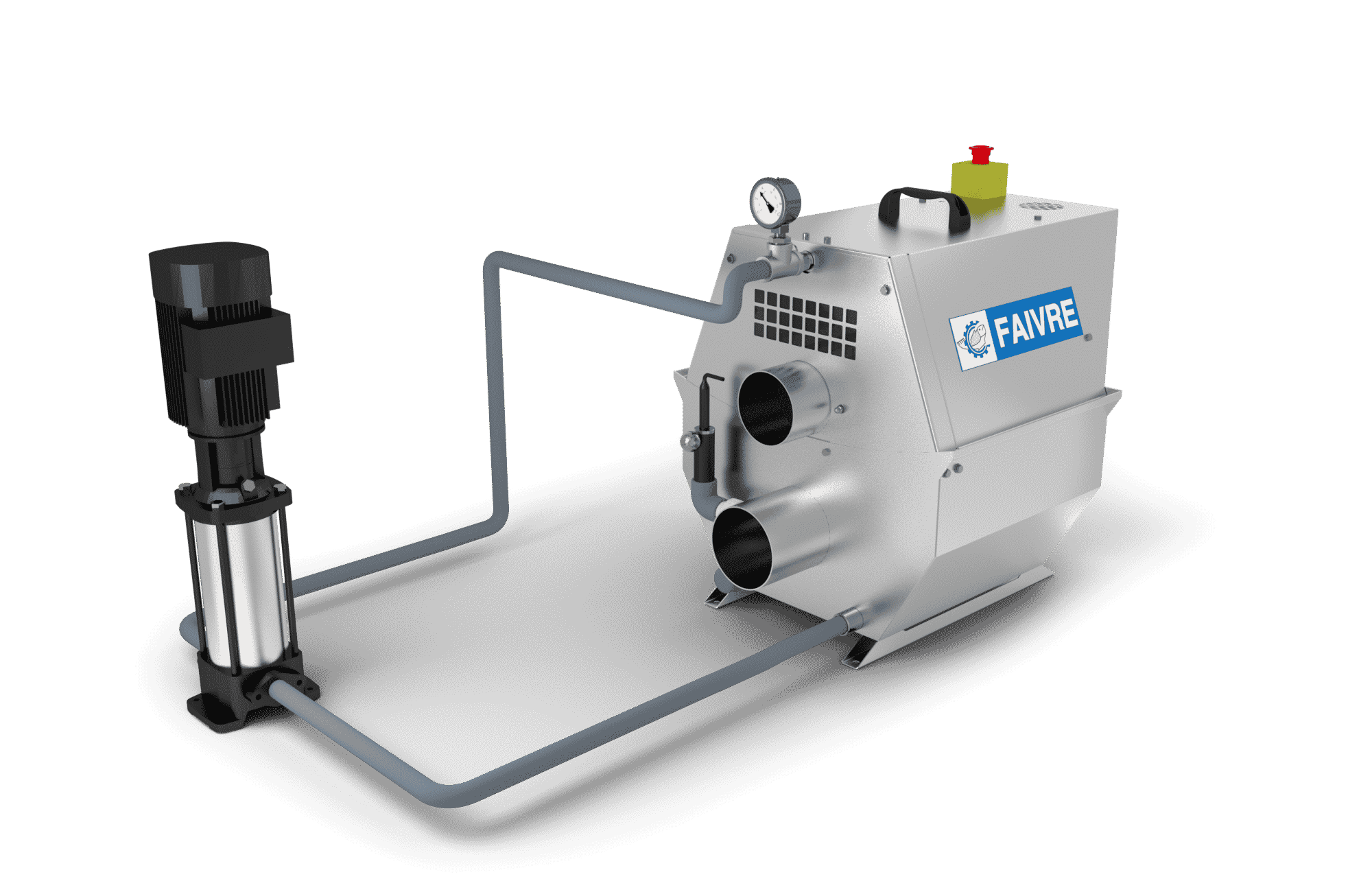

Rinsing pump

Vertical pump used to clean the filter mesh. This pump is connected to the filter cleaning ramp.

Its pressure is calculated to be adapted to the filter mesh.

The pump is delivered with all the accessories needed to connect it to the drum filter.

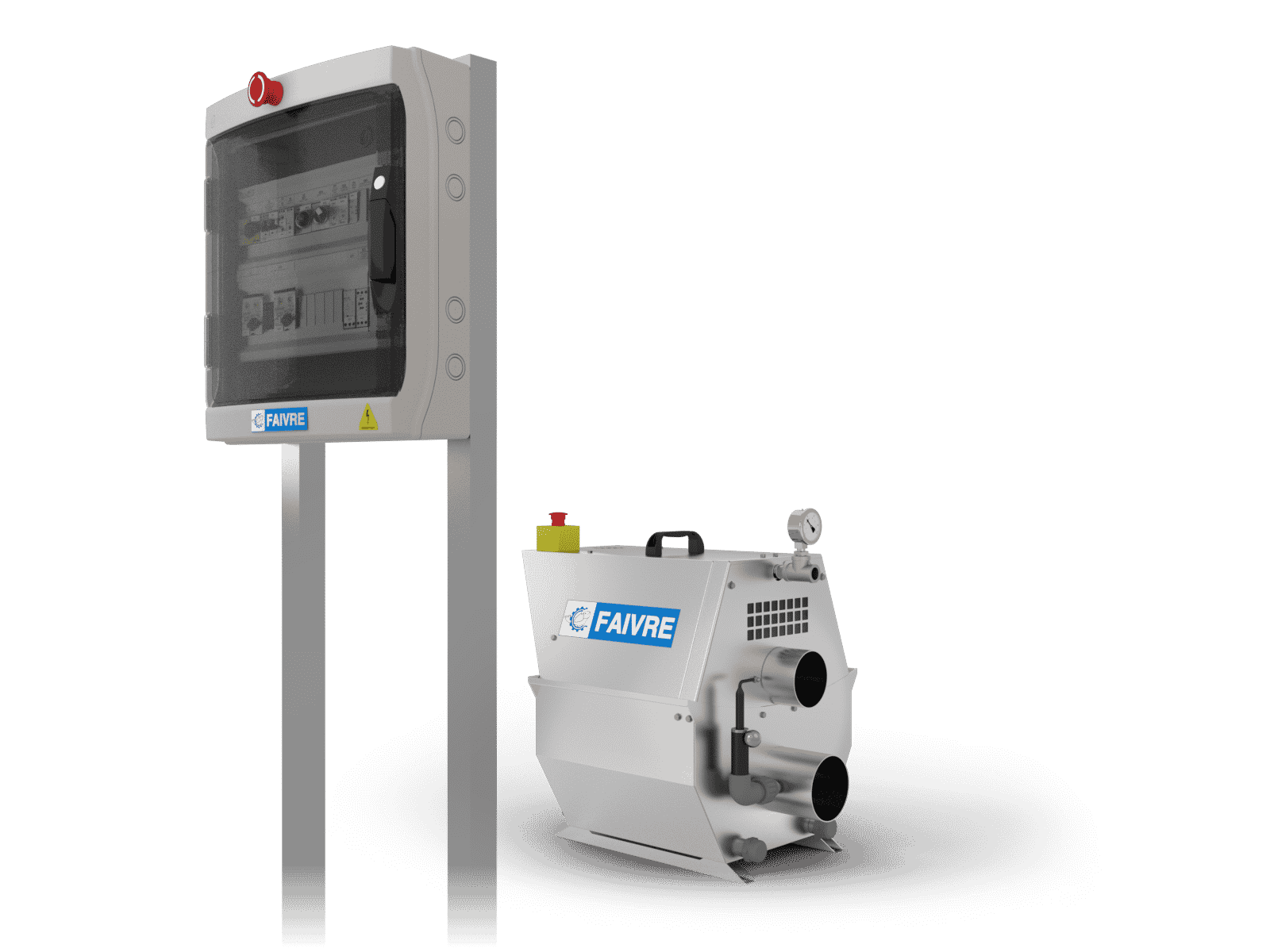

Control box

The control box is supplied as an option. It offers an optimal control and reliability for all our drum filters.

For the safety of people the box integrates :

– 1 padlockable disconnector.

– 2 emergency stops, one of which is on the front of the box, another emergency stop is placed on the drum filter.

– 1 quick release current detector is also integrated in the box. This current detector stops the filter instantly in case the filter would suddenly stop working. (This can happen when a too thick impurity enters the filter with the water)

For the safety of the equipment the box is equipped with :

– 1 Circuit breaker block for the power supply of the box.

– 2 Thermal circuit breakers for the protection of the drum filter motor and the rinsing pump motor.

The control box is supplied with :

– 5m cable for the power supply.

– 10m cable with M23 connector for easy connection of drum motor, rinsing pump, emergency stop and cover safety switch.

– 10m cable with M12 connector to easily connect the water level probe.

Part no. :

-FTC001-EAS power supply 3×200-230-400-440-480-575V 50Hz/60Hz

Level probe and/or timer

A level probe and a timer are two possible options to control the operation of the drum filter.

The level probe is a powerful radar that only takes into account the level of the liquid and that is not disturbed by foam deposits on the surface of the filtered liquid.

The timer enables the drum to be switched on and off by simple programming on the component inside the box using a screwdriver.

These two options are available separately or combined on the box, please specify when ordering.

Part no. :

– FTDSN4 LR2050 Level Radar

– FTDT01 Timer for FTC001-EAS” cabinet

Drum filters – Drum Filters 60 Series

DOWNLOADABLE DOCUMENTATION

Click on the language of your choice to download the brochure in pdf format.

Click on the language of your choice to download the brochure in pdf format.

Plans

Ø80

- FT08000B.PDF

- FT08000C.PDF

- FT08000C_CONVOYEUR.PDF

- FT08000C_Ø315.PDF

- FT08000N_Ø200.PDF

- FT08000N_Ø250.PDF

- FT08000N_Ø315.PDF

- FT08000P_Ø200.PDF

- FT08000P_Ø250.PDF

- FT08000P_Ø315.PDF

Ø200

Products of the same range

Need a quote?

Request a quote by filling in the form!

Our sales team and technicians will get back to you as soon as possible with a quote suited to your needs.